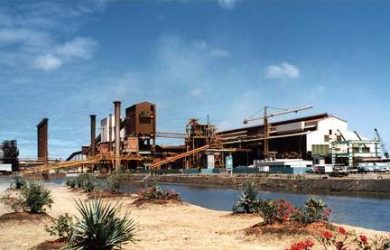

Nickel Mine New Caledonia

Incident

Electrical fire in power substation at a nickel mine in New Caledonia

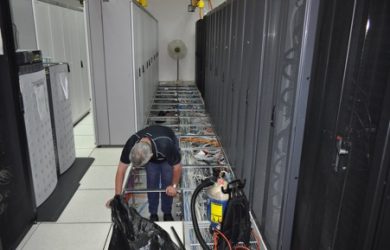

Solutions provided

- Initial expert consultation and assessment

- Scientific swap sampling to determine breakdown of contaminants present

- Mobilisation of project manager and specialist restoration supervisors from Australia

- Air Freight of equipment, chemicals and supplies to required perform work

- Organisation and management of local French speaking labour to assist with general structural restoration – and overcoming language challenges

- Technical electrical restoration of substation equipment

- Restoration and repainting of substation structure

- Restoration and recovery complete within two weeks resulting in significant BI savings and return to normal operation of mine