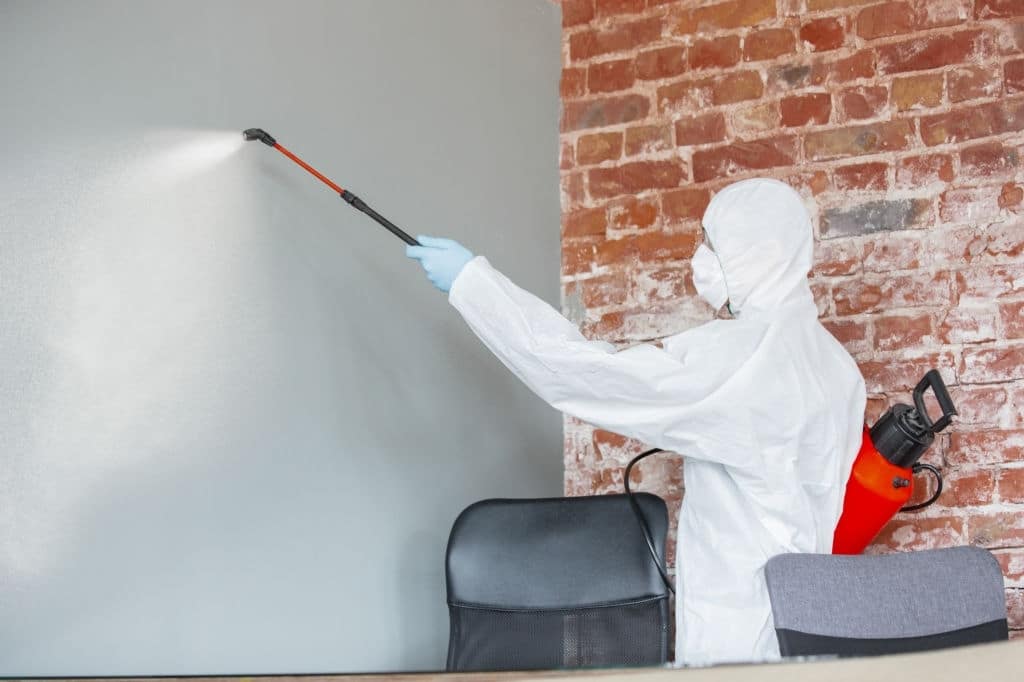

Steamatic Best Practices in Mould Remediation

Posted 3 years ago in Mould Remediation, Uncategorized

- Assignment of water damage project to Steamatic.

- Mould discovery while mitigating water-damaged area. Verification if the mould is event-driven or a pre-existing one.

- Communicate square meterage to the insurer affected by the mould and repair of the water source.

- Cease all work and ask for direction from the stakeholder/s (MIP’s)

- If the area is less than 10 square meters, Steamatic will follow the best practices as laid down for mould remediation.

- If the visible mould growth is less than 10 square meters in a contiguous area, an environmental professional is needed for assessing the scope of the work.

- There is a passage of post-clearance; the client is billed for the mitigation and remediation project.

- After remediation is complete, Steamatic will contact the IEP for post clearance testing of the previously affected area.

- If Post clearance fails, Steamatic will re-clean 犀利士

the concerned area. - The IEP will perform the assessment and send the samples to the laboratory.

- IEP will re-test the affected area; Steamatic passes, and bills the client for the mitigation and remediation project.

- Steamatic will perform the remediation to the scope of work for the IEP.

- IEP sends the Scope of Work to Steamatic.